How to deal with the problem of circulating water aquaculture

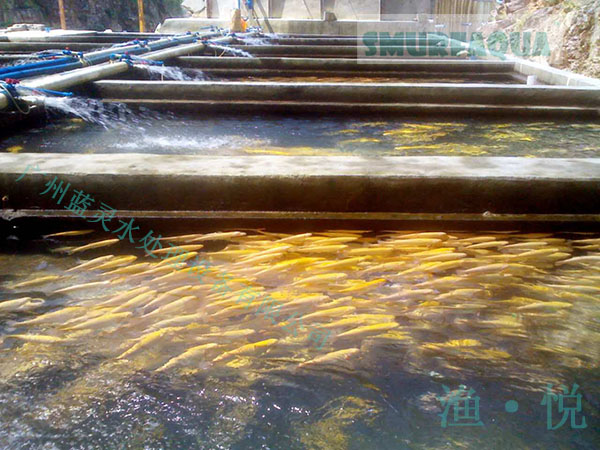

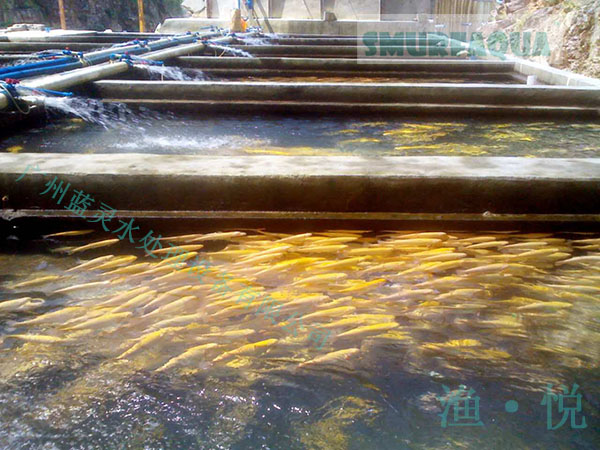

Circulating aquaculture model is a kind of environmental protection and high efficiency aquaculture model. It is not affected by external factors such as water quality, environment and weather, and can be operated intensively. Foreign countries have already completed the industrialization of the fishery industry. At home, development lags for a variety of reasons. According to the feedback from our customers, we feel it is a long way to go to promote the circulating aquaculture model. The reasons can be summarized as follows:

First. high investment cost in the early stage.

Investment in the early stage of circulating water aquaculture includes land leasing, civil construction and greenhouses, equipment procurement, transmission lines, and even road laying. Because most aquaculture farms are located far from cities, the operation of all kinds of goods is difficult. And such as land and other resources, may require a large one-time expenditure. Those who want to build greenhouses nearby in coastal areas need special steel structure greenhouses to prevent typhoon damage, and the cost is relatively high. Northern greenhouses should also take into account the problem of heat preservation. Therefore, there is no strong ability to resist risks, in the early stage of the construction of factory circulating water farm must be fully demonstrated, reasonable budget.

In addition, the cost of the complete set of circulating water equipment is not low. Of course, it's ok to raise sea fish in the desert with recycled water, but it's just a matter of cost. Without cheap heat or water, the cost of heating and changing water alone will not support the farm's profitability. It is the key to reduce the long-term operation cost of circulating water aquaculture to make use of water source or heat source on site according to local conditions. Therefore, at present, there are few inland circulating aquaculture systems. This is also the lack of a full set of samples within the industry.

To solve the problem of circulating aquaculture model promotion. We have fully communicated with many customers engaged in factory aquaculture transformation. In terms of infRAStructure construction, we recommend that customers reduce costs as much as possible according to their local conditions and economic capabilities. Many customers like to buy FRP fish ponds before, but the cost of PP plastic fish ponds is lower. And there is more room for improvement. If you have a long-term contract with the landowner, consider using a cement pond to build a fish pond. If it's short-term, consider using a canvas pond.

Second.The system consumes too much energy.

In addition to the large initial investment, most of the operating costs come from the energy consumption of the system. For example, in some areas of the north, if there is no nearby cheap heat source, simply using aquaculture heat pump, power consumption is not a small amount. The working time of the heat pump is not necessarily 24 hours, it just keeps the temperature of the aquaculture water at the set temperature. If the thermal insulation measures of the plant are not in place, the heat will be released quickly and the electricity consumption of the heat pump will increase. That, in turn, could save a significant amount of electricity. Therefore, factory circulating water farm in the site selection, close to some heat source enterprises such as fertilizer plant, power plant is a better choice.

The problem of too high energy consumption can be started from many aspects. We have many years of experience in engineering design and field construction. The following Suggestions are put forward:

1. Aquaculture farms with large water bodies can build large biochemical filtration ponds. To meet the needs of high density circulating water aquaculture. Ammonia nitrogen and nitrite in water are a headache at high density. Biological filtration is overloaded. Biological filtration as much as possible for drip biological filtration. Because it works best. In addition, special attention should be paid to the importance of biological filtration. The form of biological filtration and the total amount of filter material are the important factors influencing the effect of biological filter. According to the present experience, the trickle-flow biological filtration and tidal biological filtration have better effects.

Second.The system consumes too much energy.

In addition to the large initial investment, most of the operating costs come from the energy consumption of the system. For example, in some areas of the north, if there is no nearby cheap heat source, simply using aquaculture heat pump, power consumption is not a small amount. The working time of the heat pump is not necessarily 24 hours, it just keeps the temperature of the aquaculture water at the set temperature. If the thermal insulation measures of the plant are not in place, the heat will be released quickly and the electricity consumption of the heat pump will increase. That, in turn, could save a significant amount of electricity. Therefore, factory circulating water farm in the site selection, close to some heat source enterprises such as fertilizer plant, power plant is a better choice.

The problem of too high energy consumption can be started from many aspects. We have many years of experience in engineering design and field construction. The following Suggestions are put forward:

1. Aquaculture farms with large water bodies can build large biochemical filtration ponds. To meet the needs of high density circulating water aquaculture. Ammonia nitrogen and nitrite in water are a headache at high density. Biological filtration is overloaded. Biological filtration as much as possible for drip biological filtration. Because it works best. In addition, special attention should be paid to the importance of biological filtration. The form of biological filtration and the total amount of filter material are the important factors influencing the effect of biological filter. According to the present experience, the trickle-flow biological filtration and tidal biological filtration have better effects.

2. Excessive power consumption of water pump. We suggest minimizing the power and quantity of water pumps. In terms of design, after years of painstaking exploration, it is recommended to use microfilter and main circulation pump to reduce the energy loss of the system. Because, if you use a filter cylinder or something like that, there's no less than two pumps in a single line system. If a microfilter with automatic backwashing is used, the water pump is in the rear, and the equipment such as the ultraviolet sterilizer and the heating and cooling machine in the back can only use this water pump. In addition, when selecting pumps, use low head, high flow pumps as much as possible. Axial flow pump is a good choice. In the design of biological filtration, the water level drop should be considered. As far as possible, the bio-filtered water only USES the head pressure of the front pipe instead of another water pump.

3. Choose the equipment with the highest cost performance and the best effect. For example, many people use an oxygen machine. How can the pure oxygen it produces dissolve into water? I've seen a lot of people diffusing pure oxygen into water with ordinary aerosols, and the bubbles are about 3mm in diameter, so the bubbles stay in water for a very short time, and a lot of pure oxygen is wasted. The use of the ultra-micro bubble generator, because the diameter of the bubbles produced is generally less than 0.1mm, the efficiency of oxygen dissolution is greatly increased. Only in this way can the equipment be fully used.

4. Take certain energy protection measures. One of our customers USES a water cooler to cool the water in an open fish pond. Because the fish pond was open, the water had just cooled down, but the hot air around it had warmed up again. Therefore, under the condition of using heat pump or cold water chiller, the circulating water farm should be in the design stage, and the thermal insulation of the plant should be taken as the key subject for a good study.

Third, agricultural subsidy sequela.

In some areas, such as shandong province, there have been large-scale reforestation of circulating water and "benefiting the people" policy of equipment subsidy by relevant departments. As a result, when it comes to equipment procurement, subsidies are applied only when equipment is purchased from a designated manufacturer. As a result, farmers pay high prices for the equipment, but the effect is greatly reduced. Since then, there have been a lot of prejudice against the factory circulating water aquaculture equipment.

For customers who are skeptical about the effectiveness of factory recycling aquaculture, walk more, look more, compare more. Seeing is better than hearing. Sometimes, what you see is not true. We should be responsible for our own investment, it is always good to use more thought.

Fourth, full street style, concept hype wind.

In some industries, the unspoken rule, with 10 grams of ozone machine pretend to be 50 grams, the price is naturally lower than the general price by a large margin. A supposedly sino-foreign joint venture, a recycling water treatment equipment company, has equipped a 300-cubic metre aquaculture farm with a system that can handle only 30 cubic metres of water. Because the customer only value the price, so gave up the lanling plan. The result, of course, was a small horse-drawn wagon, which was eventually abandoned. Some companies that have just started a year or just changed careers from another industry can claim to have 30 years of experience. More people take advantage of people's worship of foreign countries and are keen to use so-called foreign experts as their platforms. Some companies have done extremely well in marketing, and they have been featured in TV stations and exhibitions, which have become the only one in the world. However, they have not been able to offer truly valuable technologies and products, and there is no video about products for people to see. What's more, when the TV station interviews, it starts the circulating water system to carry out the recording and broadcasting. After the reporter leaves, it still adopts the aquaculture of running water. "Marketing without a good product is a fraud," says one well-known entrepreneur. Therefore, we should not easily believe the so-called "foreign experts" and "big gods" of deception, you should know more about the product itself knowledge, more to the site or manufacturers field inspection. To prevent the occurrence of "** * medicated wine", "** * vaccine" and other things, when you use up, the waist is not sour, the legs are not painful, en.......... the breathing also stopped.

Fifth. some key technologies of circulating water need to be improved.

The core problem of circulating aquaculture is the removal of nitrite. Because the water has not been changed for a long time, and the feed is still being added to the water in the process of breeding, the concentration of nitrogen elements in the water is accumulated to a certain extent and cannot be discharged from the water. The concentration of nitrite will gradually increase. However, the existing biological filtration method mainly USES aerobic nitrifying bacteria to treat ammonia nitrogen and nitrite. The product is ultimately nitrate. When nitrate accumulates to a certain concentration, it is easy to become nitrite again in anoxic environment. So. Taking nitrogen out of water is the fundamental solution to the problem. Denitrifying bacteria can reverse decompose nitrite and nitrate into nitrogen which escapes from water. But in most cases, they only work in anaerobic environments. And aquaculture water environment is often high dissolved oxygen. Therefore, it is difficult to culture anaerobic denitrifying bacteria in circulating water.

After years of development, lanling water treatment equipment has established close communication with Chinese academy of sciences, pearl river fisheries research institute, guangdong petrochemical research institute and other research institutions. A considerable breakthrough has been made in the study of aerobic denitrification. At present, the experiment of aerobic denitrification has been successful. But it will take some time for the technology to become widely available because we need to authenticate, evaluate and protect new technologies. We believe that if the technology led by lanling is popularized, it will play a revolutionary role in promoting the aquaculture industry.

Sixth Excessive moisture content of seedlings, additives and feed.

It is believed that many farmers have bought fake medicine, fake feed and fake South American white prawn seedlings. This requires us to see more curative effect and less advertisement in the process of breeding. Refining a pair of "fire eyes and golden eyes" is the first successful step in aquaculture.

Seventh.

If you lack basic knowledge or experience in aquaculture, you should learn more. Keep up with The Times. We should not blindly pursue low prices. Low price may make you happy for a while, but without profit support, how can you have good after-sales service? We should not blindly follow other people's patterns, but go our own way.

Finally, I wish my friends who have read the above content a successful breeding and a great fortune!