Introduction

Automatic backwash drum filter Ⅱ is the latest improved drum filter based on the automatic backwash drum filter of the Guangzhou Lanling aquaculture equipment Co., Ltd. Not only does it inherit all the advantages of the first drum filter, it also improves its function according to a large sum of advice from the clients. Now the second one is almost perfect in every aspect.

Structure and fundamental

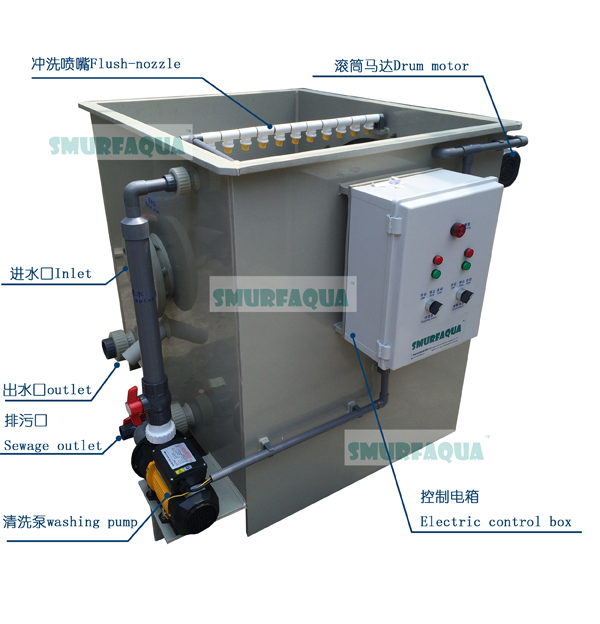

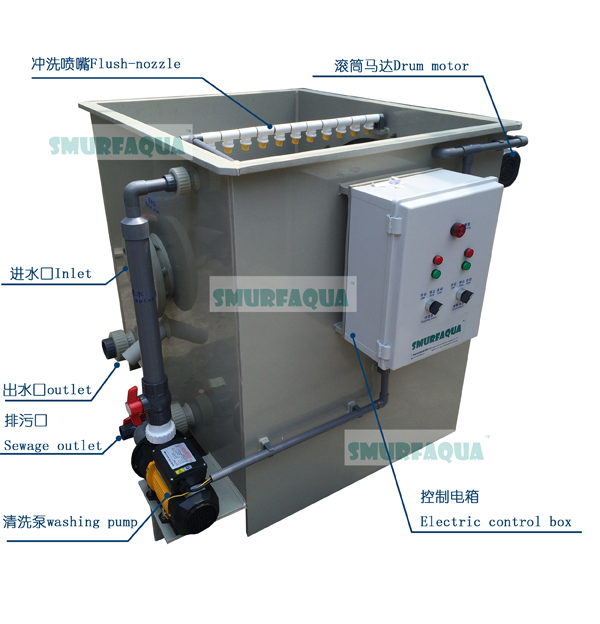

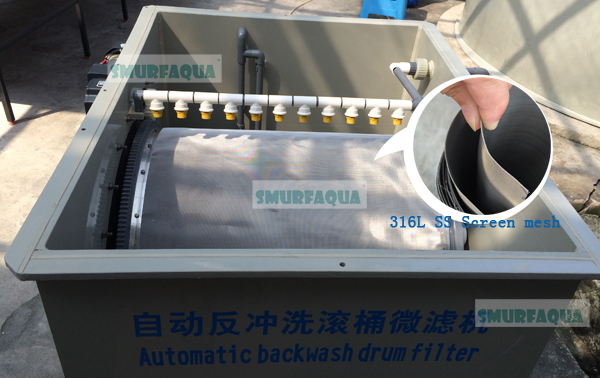

The drum filter functions by a rotatable stainless steel drum, with a dense 316L stainless steel mesh on the surface. The drum is powered by a motor through gears. Outside the filter body, there is a plastic booster pump connecting to a row of flush-nozzles. Inside the filter body, there are two water level controllers to transmit signal to the electric control box on the basis of the water level, in which way the electric control box can control other devices efficiently. There are a relatively big inlet, a small outlet and a sewage outlet on the filter body. Water drains from the outlet connected to the pump. All the automatic devices of the drum filter are controlled by the electric control box outside the filter body.

Structure and fundamental

The drum filter functions by a rotatable stainless steel drum, with a dense 316L stainless steel mesh on the surface. The drum is powered by a motor through gears. Outside the filter body, there is a plastic booster pump connecting to a row of flush-nozzles. Inside the filter body, there are two water level controllers to transmit signal to the electric control box on the basis of the water level, in which way the electric control box can control other devices efficiently. There are a relatively big inlet, a small outlet and a sewage outlet on the filter body. Water drains from the outlet connected to the pump. All the automatic devices of the drum filter are controlled by the electric control box outside the filter body.

Function

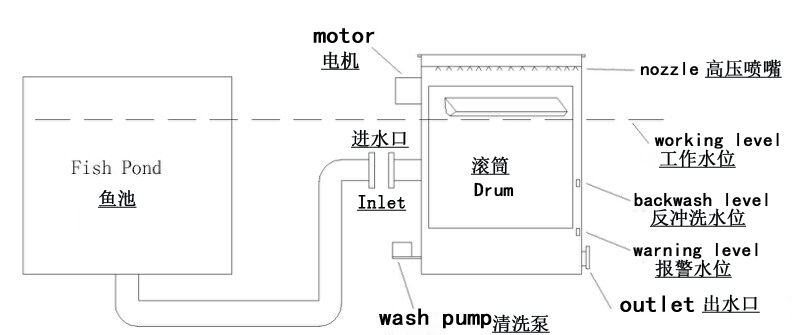

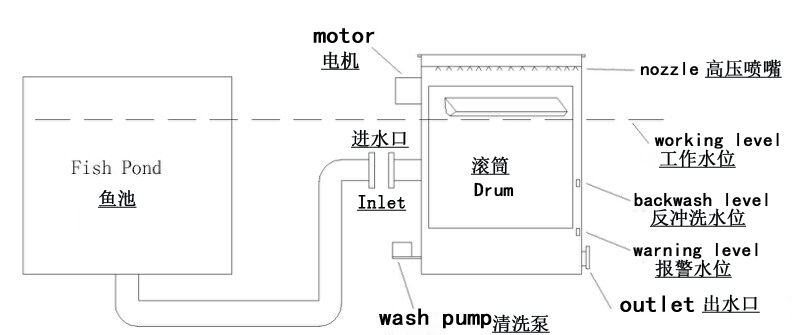

The drum filter should be placed flush with the disposal water. Sewage flows into the filter body automatically. After turning on the sewage pump, water level outside the filter body will descent, while water will be flowing outside from the inside of the filter body. The dirt in the water is to be blocked by the stainless steel mesh. After functioning for a while, the more dirt the stainless steel mesh blocks, the bigger the water resistance becomes. But the sewage flow remains the same due to the stable function of the water pump, so the water level outside the filter body descents gradually. When the water level decreases to where the water level controller is, the controller will transmit signal to the control center by electricity, and then the motor power and the booster pump will be turned on. While the drum filter starts to roll, water will be blown out from the high-pressure pump to wash away the dirt clinging to the mesh. The dirt will be collected by the dump tank and then discharged from the sewage pipe. This is the process to separate solid and liquid.

Function

The drum filter should be placed flush with the disposal water. Sewage flows into the filter body automatically. After turning on the sewage pump, water level outside the filter body will descent, while water will be flowing outside from the inside of the filter body. The dirt in the water is to be blocked by the stainless steel mesh. After functioning for a while, the more dirt the stainless steel mesh blocks, the bigger the water resistance becomes. But the sewage flow remains the same due to the stable function of the water pump, so the water level outside the filter body descents gradually. When the water level decreases to where the water level controller is, the controller will transmit signal to the control center by electricity, and then the motor power and the booster pump will be turned on. While the drum filter starts to roll, water will be blown out from the high-pressure pump to wash away the dirt clinging to the mesh. The dirt will be collected by the dump tank and then discharged from the sewage pipe. This is the process to separate solid and liquid.

When the dirt in the drum filter is being washed, the water levels of both outside and inside are the same again with the stirring of the drum filter, and then the filter is about to enter the next cycle.

Instructions

1.The drum filter can function backwash and filter simultaneously. Additionally if the filter does not function backwash, the drum is still, which spends little electricity.

2.The upper limb of the filter body is higher than the surface of disposal water, so there is no worry for the water to brim.

3.When the water level is lower than the warning water level, the control center of the drum filter will alarm and turn off the sewage pump, in case that the sewage pump damages itself by racing.

4.If there is malfunction such as short circuit, the leakage switch in the control center of the drum filter will cut off electricity automatically.

Improvements

Instructions

1.The drum filter can function backwash and filter simultaneously. Additionally if the filter does not function backwash, the drum is still, which spends little electricity.

2.The upper limb of the filter body is higher than the surface of disposal water, so there is no worry for the water to brim.

3.When the water level is lower than the warning water level, the control center of the drum filter will alarm and turn off the sewage pump, in case that the sewage pump damages itself by racing.

4.If there is malfunction such as short circuit, the leakage switch in the control center of the drum filter will cut off electricity automatically.

Improvements

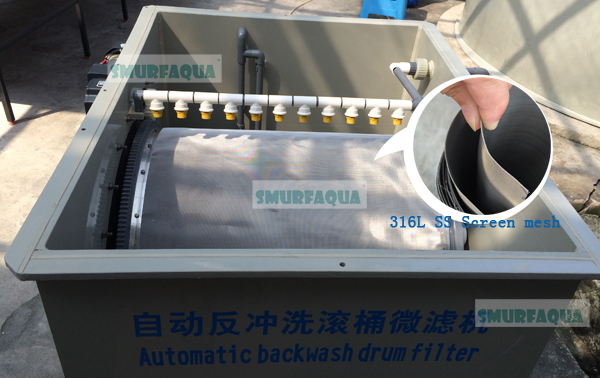

1.The drum filter Ⅱhas a real custom 316L stainless steel mesh, capable to resist acid liquid at more than PH 11. Special weaving pattern greatly increases the strength of the mesh in case that the mesh is broken easily. The section of the mesh is presented above:

2.The drum filter is powered by gears rather than central axis, so the moment is smaller and the consumed electricity is negligible.

3.The drum and mesh can be dissembled conveniently. The drum has an outside flange so that it is easier to mend, replace and clean.

4.。The drum filter has two bearings, making moments of force small and even while the drum is rolling so as to avoid uneven wear of the rubber seal.

5.The latest design of the internal and external seal can perfectly divide sewage and clean water. It also prevents the rubber seal from quickly wearing. Lanling Aquaculture will provide another rubber seal as substitute.

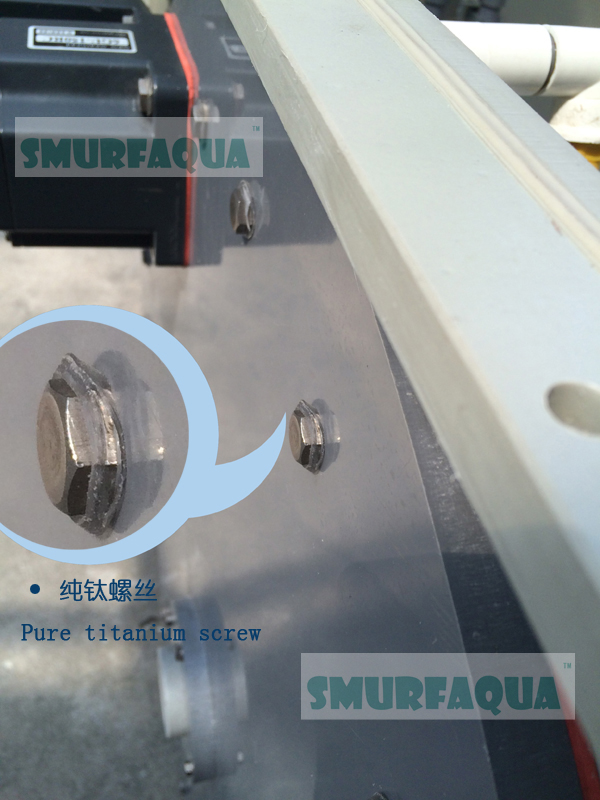

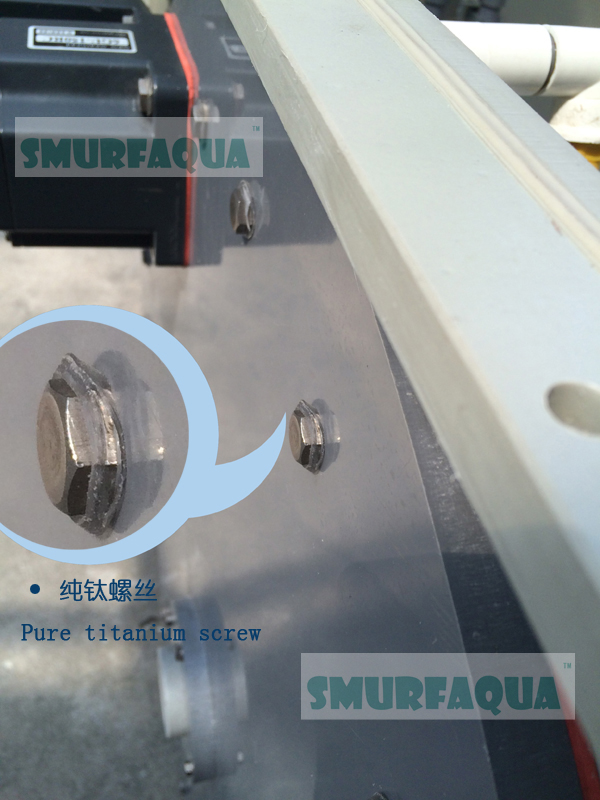

6.Corrosion-resistant materials are applied on the devices in water. The filter body is made of PP plastic (for food) and the drum is made of PVC (for food). The mesh is made of real 316L stainless steel. The rubber seal is made of wearable sulfate glue made in 50 degrees Celsius. The screws are all made of silver.

7.The outlet pipe is connected to the pump, increasing the effective filtration area and decrease the frequency of backwash during filtering process. In this way, the subsidiary devices can be powered by the water from the outlet directly, so as to reduce the number of pumps applied in the filter system.

8.Backwash can be controlled by water level, time, interval, manual operation, etc.

9.The water level controller is a non-contact electromagnetic controller. Unlike ordinary water level controllers, it can effectively prevent breakdowns owing to seawater corrosion or foreign matters.

10.。The electric control box consists of imported circuit elements. The control should be less than 24V. Multiple control methods of low voltage ensure the control system. The water level controller at the bottom can alarm to the control center and cut off electricity of the water pump instantly in case of the drum racing itself.

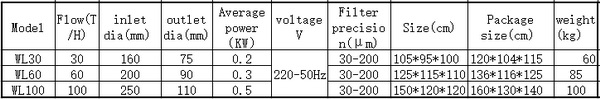

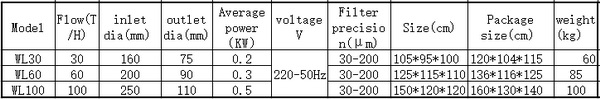

Specification

Applicable industries

Aquaculture, sewage treatment plant, chemical plant, food factory, etc.

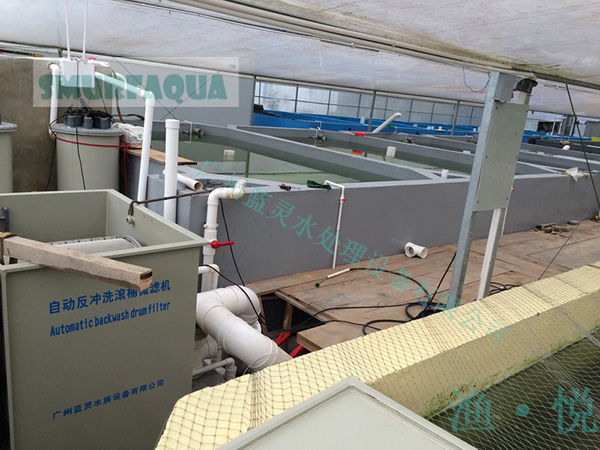

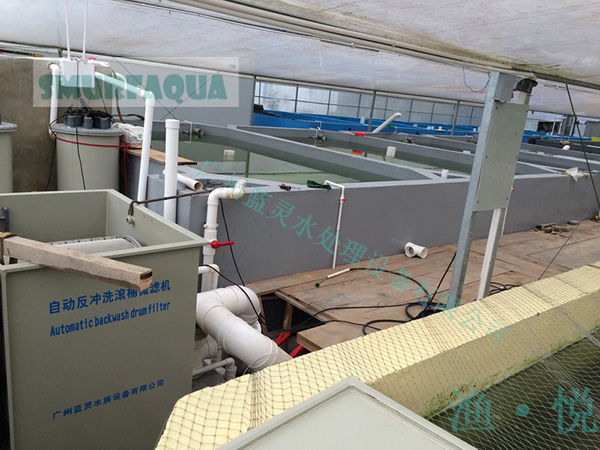

indoor shirmp farm,the RAS:

indoor seawater fish farm:

Comparison of cultured sewage before and after passing the microfilter: